High-Precision Grid Technology at MHB Battery: Continuous Casting – Rolling – Punching – Pasting

Advanced Grid Technology at MHB Battery: Continuous Casting – Rolling – Punching – Pasting

At MHB Battery, we utilize a cutting-edge continuous grid production process—including casting, rolling, punching, and pasting—to manufacture high-performance lead-acid Battery Plates. This fully automated system ensuresprecise grid geometry, enhanced conductivity, and improved corrosion resistance, laying a solid foundation for reliable energy storage solutions across industrial and automotive applications.

Step-by-Step Precision in Grid Manufacturing

1. Continuous Casting

The process begins by melting high-purity lead ingots and casting them into thick, narrow lead strips. Unlike traditional gravity casting, this continuous method provides a stable metal flow, resulting in a uniform microstructure with fewer internal defects. This ensures consistency from the very beginning of the production line.

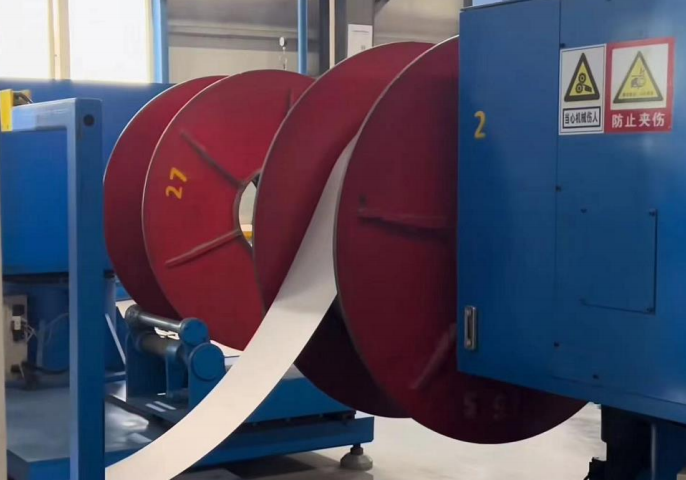

2. Continuous RollingThe cast lead strip is then precisely rolled into thin, wide strips using advanced rolling mills. This step greatly reduces the presence of air voids and inconsistencies, enhancing grid density and strength. The resulting strip is ideal for shaping into current-conducting battery plates.

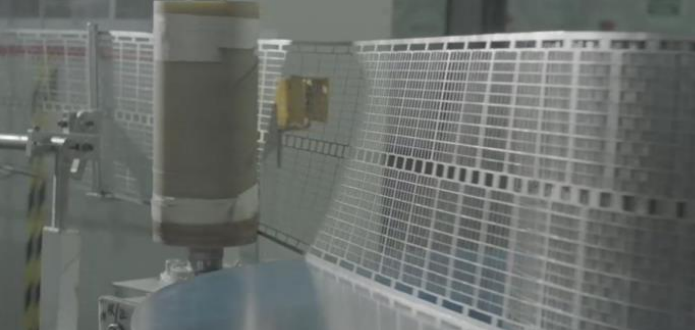

3. Continuous Punching

Next, the rolled lead strip is fed into a high-speed punching system that creates continuous rolls of grids. The punching process forms the framework of the battery plate—called the grid—where the uniformity of bar thickness and pattern directly improves electrical conductivity and structural stability.

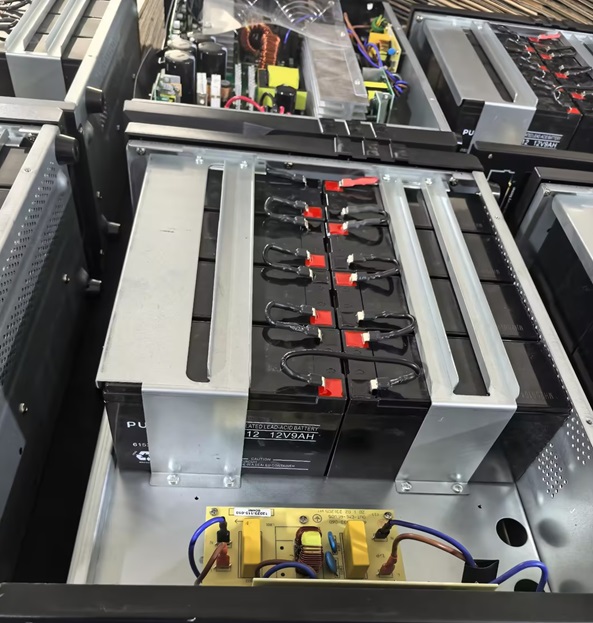

4. Continuous Pasting and Curing

Once punched, the grids are automatically coated with a specialized lead paste designed for optimal electrochemical performance. These pasted grids are then cut to size and sent into a controlled curing chamber, where humidity and temperature are regulated to harden and stabilize the plates for long-term use.

Why It Matters: The Benefits of MHB’s Continuous Grid Technology

MHB Battery's investment in automated grid production technology brings multiple technical and operational advantages over conventional methods:

-

Refined Metal Structure: Stronger and more resistant to corrosion.

-

Uniform Grid Bars: Improved paste adhesion and current flow.

-

Better Conductivity: Reduced internal resistance, better energy output.

-

Superior Process Control: Higher production consistency and reliability.

-

Enhanced Plate Strength: Ideal for deep-cycle and high-vibration environments.